5.1.2.4. LTC LTC6811-1-based 12-Cell BMS-Slave 2.1.6 and above

Note

The changelog for this release is found at Section 5.1.2.1.2.

5.1.2.4.1. Overview

Important

The following description only applies for the

LTC LTC6811-1-based 12-Cell BMS-Slave

versions 2.1.6 and above.

Hint

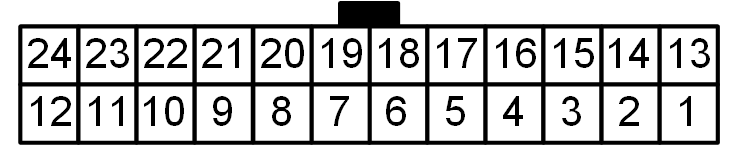

All connector pinouts described below follow the Convention for Molex Micro-Fit 3.0 Connector Pin Numbering.

5.1.2.4.2. Pinout Overview

The pinout of this BMS-Slave is shown in the Fig. 5.5 and Table 5.27.

Fig. 5.5 Connector placement of the LTC LTC6811-1-based 12-Cell BMS-Slave 2.1.6 and above.

Connector ID |

Functionality |

Pinout |

|---|---|---|

X200 |

Cell voltage measurement |

|

X201 |

Temperature sensors |

|

X202 |

Temperature sensors |

|

X500 |

isoSPI Daisy Chain input |

|

X501 |

isoSPI Daisy Chain output |

|

X502 |

isoSPI Daisy Chain input |

|

X503 |

isoSPI Daisy Chain output |

|

X1001 |

External DC supply |

|

X1002 |

External DC supply |

5.1.2.4.3. Specifications

5.1.2.4.3.1. Electrical Ratings

The current consumption from the module has been measured at 43.2 V module voltage, which is equivalent to a cell voltage of 3.6 V per cell. No sense lines have been connected from this measurement (as the impact of cell voltage sensing is negligible on the current consumption).

The DC supply current has been measured with a voltage of 12 V and no

VBAT or cells connected.

Description |

Minimum |

Typical |

Maximum |

Unit |

|---|---|---|---|---|

Battery Module Voltage |

11 |

– |

60 |

V |

Single Battery Cell Voltage |

0 |

– |

5 |

V |

Temperature Sensor Inputs |

– |

10k |

– |

\({\Omega}\) |

Analog Inputs (pin headers) |

0 |

– |

5 |

V |

Digital Inputs/Outputs (pin headers) |

0 |

– |

5 |

V |

External DC Supply |

8 |

12 |

24 |

V |

Current consumption: Primary in sleep, Secondary in sleep |

– |

9.1 |

– |

\({\mu}A\) |

Current consumption: Primary active, Secondary in sleep |

– |

11.64 |

– |

mA |

Current consumption: Primary active, Secondary active |

– |

22.33 |

– |

mA |

DC supply current: Primary in sleep, Secondary in sleep |

– |

4.3 |

– |

mA |

DC supply current: Primary active, Secondary in sleep |

– |

73.6 |

– |

mA |

DC supply current: Primary active, Secondary active |

– |

144.3 |

– |

mA |

5.1.2.4.3.2. Mechanical Dimensions

Description |

Value |

Unit |

|---|---|---|

Width |

100 |

mm |

Length |

160 |

mm |

Height |

15 |

mm |

Weight |

83 |

g |

5.1.2.4.3.3. Block Diagram

The block diagram of the BMS-Slave is shown in Fig. 5.6.

Fig. 5.6 BMS-Slave 12-Cell Block Diagram

5.1.2.4.3.4. Schematic and Board Layout

More information about the board schematic and layout files can be found in section Design Resources.

5.1.2.4.4. Functions

The following general description applies to both, the primary and the secondary of the BMS-Slave. If there are any differences in hardware between the primary and the secondary they will be marked as such.

5.1.2.4.4.1. Cell Voltage Measurement

The cell voltage sense lines are input on the connector X200. The pinout is described in Table 5.30.

Pin |

Signal |

Direction |

Description |

|---|---|---|---|

1 |

|

Input |

Battery module negative terminal |

2 |

|

Input |

Cell 0 positive terminal |

3 |

|

Input |

Cell 2 positive terminal |

4 |

|

Input |

Cell 4 positive terminal |

5 |

|

Input |

Cell 6 positive terminal |

6 |

|

Input |

Cell 8 positive terminal |

7 |

|

Input |

Cell 10 positive terminal |

8 |

|

Input |

Battery module positive terminal |

9 |

not connected |

- |

- |

10 |

not connected |

- |

- |

11 |

not connected |

- |

- |

12 |

not connected |

- |

- |

13 |

|

Input |

Cell 0 negative terminal |

14 |

|

Input |

Cell 1 positive terminal |

15 |

|

Input |

Cell 3 positive terminal |

16 |

|

Input |

Cell 5 positive terminal |

17 |

|

Input |

Cell 7 positive terminal |

18 |

|

Input |

Cell 9 positive terminal |

19 |

|

Input |

Cell 11 positive terminal |

20 |

not connected |

- |

- |

21 |

not connected |

- |

- |

22 |

not connected |

- |

- |

23 |

not connected |

- |

- |

24 |

not connected |

- |

- |

Each of these lines is protected by a 250mA fast fuse surface mount device

(F301 - F313) on the board except of the VBAT+ and VBAT- lines which are

protected by a value of 500mA (F300 and F314).

This is especially important for a test environment.

The VBAT+ and VBAT- connections are used for the internal power supply of

the BMS-Slave board.

If the battery module does not contain these separate wires to the positive and

negative module terminals, the solder jumpers SJ401 and SJ402 have to be

shorted.

In this case the power required by the BMS-Slave will be supplied through the

sense lines CELL_0- and CELL_11+.

Running the BMS-Slave in this configuration could result in cell measurement

errors due to voltage drop over the sense wires.

The cell input lines are filtered by a grounded or differential capacitor filter: both possibilities are provided on the PCB of the BMS-Slave. More information on the corner frequency of this filtering can be found in the schematic. The grounded capacitor filter should be used in environments affected with a high noise as it offers a high level of battery voltage ripple rejection. The differential capacitor filter can be used when noise is less frequent or the design is subjected to cost optimization.

5.1.2.4.4.2. Passive Cell Balancing

The passive balancing circuit is realized by a parallel connection of two 68 \({\Omega}\) discharge resistors that can be connected to each single cell in parallel. The MOSFET switches (T1500 - T1511) that control the connection to the cells are controlled by the primary LTC LTC6811-1 monitoring IC. The secondary LTC LTC6811-1 does not support balancing. The resistor value of 2x 68 \({\Omega}\) results in a balancing current of about 100mA at a cell voltage of 3.6V. This current results in a power dissipation of about 0.36W per balancing channel (at 3.6V).

5.1.2.4.4.3. Global Cell Balancing Feedback

In order to check the proper function of the balancing process or to detect a malfunction in the balancing circuit, a global balancing feedback signal is connected to the LTC LTC6811-1. This allows the BMS-Master to check whether any balancing action is currently taking place. The feedback signal is connected to the GPIO3 of the LTC LTC6811-1. The signal remains in a logic zero state until any balancing action on at least one cell in the module starts.

5.1.2.4.4.4. Temperature Sensor Measurement

The cell temperature sensors are connected to the connectors X201 (primary) and X202 (secondary). The pinout is identical for the primary and secondary and is described in Table 5.31.

Pin |

Signal |

Direction |

Description |

|---|---|---|---|

1 |

T-SENSOR_0 |

Input |

NTC Sensor 0 terminal 1 |

2 |

T-SENSOR_1 |

Input |

NTC Sensor 1 terminal 1 |

3 |

T-SENSOR_2 |

Input |

NTC Sensor 2 terminal 1 |

4 |

T-SENSOR_3 |

Input |

NTC Sensor 3 terminal 1 |

5 |

T-SENSOR_4 |

Input |

NTC Sensor 4 terminal 1 |

6 |

T-SENSOR_5 |

Input |

NTC Sensor 5 terminal 1 |

7 |

T-SENSOR_6 |

Input |

NTC Sensor 6 terminal 1 |

8 |

T-SENSOR_7 |

Input |

NTC Sensor 7 terminal 1 |

9 |

|

Input |

NTC Sensor 0 terminal 2 |

10 |

|

Input |

NTC Sensor 1 terminal 2 |

11 |

|

Input |

NTC Sensor 2 terminal 2 |

12 |

|

Input |

NTC Sensor 3 terminal 2 |

13 |

|

Input |

NTC Sensor 4 terminal 2 |

14 |

|

Input |

NTC Sensor 5 terminal 2 |

15 |

|

Input |

NTC Sensor 6 terminal 2 |

16 |

|

Input |

NTC Sensor 7 terminal 2 |

Standard 10\({k\Omega}\) NTC resistors are recommended for use. When using other values than these, the series resistors (R100-1/2 to R107-1/2) on the board may have to be adjusted. Please note that the accuracy of the internal voltage reference VREF2 decreases heavily with a load of over 3mA. Using 8x 10\({k\Omega}\) NTC resistors with the corresponding 10\({k\Omega}\) series resistors results in a current of 1.2mA (at 20°C) which is drawn from VREF2.

Each of the 8 temperature sensors are connected to an analog multiplexer. The analog multiplexer can be controlled via I2C by the LTC LTC6811-1 (7-bit address: 0x4C). In order to ensure fast settling times after switching the multiplexer input, the output signal of the multiplexer is buffered by an operational amplifier. Finally the analog voltage of the selected sensor is measured on the GPIO1 pin of the LTC LTC6811-1.

5.1.2.4.4.5. On-board EEPROM

Attention

The BMS-Slave hardware versions 2.1.0 and above use a different

EEPROM IC (ST M24M02) than all other previous hardware versions.

The primary as well as the secondary unit of the BMS-Slave board is equipped with an EEPROM (IC800-1/2). The EEPROM for example can be used for storing data such as calibration values or minimum and maximum temperatures seen by the module during its lifetime. Similar to the analog multiplexers, the EEPROM device is connected to the I2C bus of the LTC LTC6811-1 (7-bit address: 0x50).

5.1.2.4.4.6. On-board Ambient Temperature Sensor

For an additional monitoring of the ambient temperature an on-board temperature sensor is used. This temperature sensor can be read by the LTC LTC6811-1 via the I2C bus (7-bit address: 0x48). It is possible to program an alert temperature level. Once the measured temperature reaches this alert temperature level, the alert pin of the IC is set to a logic low level. Currently, this signal is not used on the BMS-Slave board, but it is accessible on the connector X402.

5.1.2.4.4.7. Additional Inputs and Outputs

Several additional analog and digital inputs and outputs are provided on the BMS-Slave board via pin headers. Each 16 analog inputs are provided on connector X400 (primary) and X403 (secondary). The pinout for the connectors for the primary and secondary unit is identical and is described in Table 5.32.

Pin |

Signal |

Direction |

Description |

|---|---|---|---|

1 |

ANALOG-IN_0 |

Input |

Analog input 0 |

2 |

ANALOG-IN_1 |

Input |

Analog input 1 |

3 |

ANALOG-IN_2 |

Input |

Analog input 2 |

4 |

ANALOG-IN_3 |

Input |

Analog input 3 |

5 |

ANALOG-IN_4 |

Input |

Analog input 4 |

6 |

ANALOG-IN_5 |

Input |

Analog input 5 |

7 |

ANALOG-IN_6 |

Input |

Analog input 6 |

8 |

ANALOG-IN_7 |

Input |

Analog input 7 |

9 |

ANALOG-IN_8 |

Input |

Analog input 8 |

10 |

ANALOG-IN_9 |

Input |

Analog input 9 |

11 |

ANALOG-IN_10 |

Input |

Analog input 10 |

12 |

ANALOG-IN_11 |

Input |

Analog input 11 |

13 |

ANALOG-IN_12 |

Input |

Analog input 12 |

14 |

ANALOG-IN_13 |

Input |

Analog input 13 |

15 |

ANALOG-IN_14 |

Input |

Analog input 14 |

16 |

ANALOG-IN_15 |

Input |

Analog input 15 |

17 |

+3.0V_VREF2 |

Output |

LTC LTC6811-1 3.0V voltage reference |

18 |

|

Output |

GND |

Each 8 analog inputs are connected to an analog multiplexer. The analog multiplexers can be controlled via I2C by the LTC LTC6811-1 (7-bit addresses: 0x4D and 0x4E). In order to ensure fast settling times after switching the multiplexer input, the output signals of the multiplexers are buffered by operational amplifiers. Finally the analog voltage of the selected sensor can be measured on the GPIO2 pin of the LTC LTC6811-1.

Each 8 digital inputs/outputs are provided on the connectors X401 (primary) and X404 (secondary). The pinout for the connectors for the primary and secondary unit is identical and is described in Table 5.33.

Pin |

Signal |

Direction |

Description |

|---|---|---|---|

1 |

DIGITAL-IO_0 |

Input/Output |

Digital input/output 0 |

2 |

DIGITAL-IO_1 |

Input/Output |

Digital input/output 1 |

3 |

DIGITAL-IO_2 |

Input/Output |

Digital input/output 2 |

4 |

DIGITAL-IO_3 |

Input/Output |

Digital input/output 3 |

5 |

DIGITAL-IO_4 |

Input/Output |

Digital input/output 4 |

6 |

DIGITAL-IO_5 |

Input/Output |

Digital input/output 5 |

7 |

DIGITAL-IO_6 |

Input/Output |

Digital input/output 6 |

8 |

+5.0V_VREG |

Output |

LTC LTC6811-1 5.0V regulated voltage |

9 |

|

Output |

GND |

Each 8 digital inputs/outputs are connected to an I2C controlled port expander (7-bit address: 0x20). The direction of the inputs/outputs as well as the logic levels on the pins can be selected by register settings. Each of the 8 digital inputs/outputs has a discrete pull up resistor that for example can be used for directly connecting a tactile switch.

5.1.2.4.4.8. isoSPI Daisy Chain Connection

The data transmission between the slaves and between the slaves and the basic board takes place using the isoSPI interface. The isoSPI signals are input on the connectors X500 (primary) and X502 (secondary). The isoSPI signals for daisy-chaining are output on the connectors X501 (primary) and X503 (secondary). The isoSPI connections are isolated galvanically using pulse transformers (TR1400-1/2). The voltage amplitude of the differential signal can be adjusted by setting resistors (see paragraph Daisy Chain Communication Current).

The pinout of the isoSPI connectors is described in Table 5.34 and Table 5.35.

Pin |

Daisy Chain |

|---|---|

1 |

|

2 |

|

Pin |

Daisy Chain |

|---|---|

1 |

|

2 |

|

5.1.2.4.4.9. Hardware Settings / Options

5.1.2.4.4.9.1. Software Timer

The internal software timer of the LTC LTC6811-1 can be enabled/disabled by a dedicated external pin (SWTEN, pin 36 of the LTC LTC6811-1). In order to support all features, the BMS-Slave board offers a possibility to switch the software timer. The software timer is enabled in the standard configuration, which means pin 36 is pulled to VREG via a zero-ohm resistor (R221/R321). The timer can be disabled by removing the resistor R1402-1/2 and placing a zero-ohm resistor to R1403-1/2.

5.1.2.4.4.9.2. Daisy Chain Communication Current

The daisy chain communication current can be set by the resistors R1419-1/2 and R1421-1/2. The default value is 820 \({\Omega}\) for R14211/2 and 1.21\({k\Omega}\) for R1419-1/2. This values result in a bias current of approximately 1mA and a differential signal amplitude of 1.18V. Theses values are suitable for high noise environments with cable lengths of over 50m. More information can be found in the LTC LTC6811-1 data sheet.

5.1.2.4.4.9.3. Status LED

The status LEDs LD1400-1/2 show the current mode of each, the primary and secondary LTC LTC6811-1. The LED is on in STANDBY, REFUP or MEASURE mode, whereas the LED is off in SLEEP mode. The LED can be disabled by removing the resistor R1407-1/2.

5.1.2.4.4.9.4. GPIO Extension Connector

The internal GPIO lines of the primary or secondary LTC LTC6811-1 can be connected to the GPIO extension pin header X402 via optional zero-ohm resistors. In the standard configuration these resistors are not placed. Of course it is possible to place each both resistors for a parallel connection of the internal signals to the GPIO extension connector. The placement of the resistors and the resulting connection is shown in Table 5.36.

GPIO |

connect to pin header |

connect to internal function |

|---|---|---|

1 |

R1405-1/2 |

R1406-1/2 (default) |

2 |

R1409-1/2 |

R1410-1/2 (default) |

3 |

R1412-1/2 |

R1413-1/2 (default) |

4 |

R1414-1/2 |

R1417-1/2 (default) |

5 |

R1418-1/2 |

R1420-1/2 (default) |

The pinout of the extension connector X402 is described in Table 5.37.

Pin |

Signal |

Direction |

Description |

|---|---|---|---|

1 |

+3.0V_VREF2_0 |

Output |

Primary LTC LTC6811-1 3.0V reference voltage 2 |

2 |

+3.0V_VREF2_1 |

Output |

Secondary LTC LTC6811-1 3.0V reference voltage 2 |

3 |

+5.0V_VREG_0 |

Output |

Primary LTC LTC6811-1 5.0V regulated voltage |

4 |

+5.0V_VREG_1 |

Output |

Secondary LTC LTC6811-1 5.0V regulated voltage |

5 |

PRIMARY-GPIO1-OPT |

Input/Output |

Primary LTC LTC6811-1 GPIO1 |

6 |

SECONDARY-GPIO1-OPT |

Input/Output |

Secondary LTC LTC6811-1 GPIO1 |

7 |

PRIMARY-GPIO2-OPT |

Input/Output |

Primary LTC LTC6811-1 GPIO2 |

8 |

SECONDARY-GPIO2-OPT |

Input/Output |

Secondary LTC LTC6811-1 GPIO2 |

9 |

PRIMARY-GPIO3-OPT |

Input/Output |

Primary LTC LTC6811-1 GPIO3 |

10 |

SECONDARY-GPIO3-OPT |

Input/Output |

Secondary LTC LTC6811-1 GPIO3 |

11 |

PRIMARY-GPIO4-OPT |

Input/Output |

Primary LTC LTC6811-1 GPIO4 |

12 |

SECONDARY-GPIO4-OPT |

Input/Output |

Secondary LTC LTC6811-1 GPIO4 |

13 |

PRIMARY-GPIO5-OPT |

Input/Output |

Primary LTC LTC6811-1 GPIO5 |

14 |

SECONDARY-GPIO5-OPT |

Input/Output |

Secondary LTC LTC6811-1 GPIO5 |

15 |

PRIMARY-WDT |

Output |

Primary LTC LTC6811-1 watchdog output |

16 |

SECONDARY-WDT |

Output |

Secondary LTC LTC6811-1 watchdog output |

17 |

PRIMARY-TEMP-ALERT |

Output |

Primary board T-sensor alarm output |

18 |

SECONDARY-TEMP-ALERT |

Output |

Secondary board T-sensor alarm output |

19 |

|

Output |

GND |

20 |

|

Output |

GND |

5.1.2.4.4.10. External Isolated DC- Supply

Note

The external isolated DC- supply is only available in the BMS-Slave

hardware versions 2.1.0 and above.

It is possible to supply the BMS-Slave by an external DC power supply with a voltage range of 8V to 24V. The DC input is protected against reverse voltage and over-current (with a 1.25A fuse). The external DC supply has to be connected on connector X1001 or X1002 (both connectors are in parallel for daisy chaining the supply). The pinout of the connectors X1001 and X1002 is shown in Table 5.38.

Pin |

Signal |

Direction |

Description |

|---|---|---|---|

1 |

|

Input |

positive supply terminal |

2 |

|

Input |

negative supply terminal |